What is Lineation?

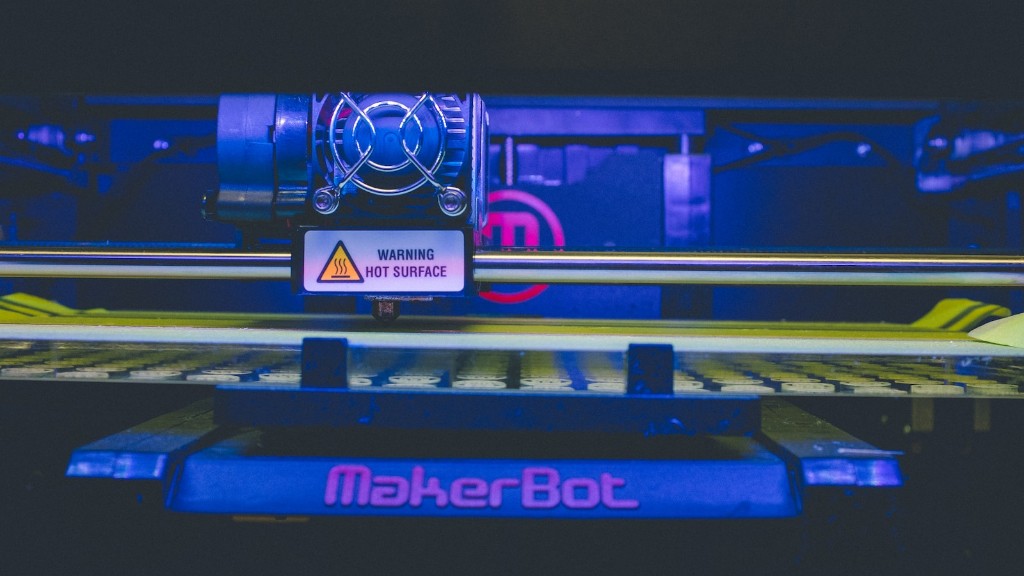

Lineation or set off is the phenomenon of a sheet of paper printed with distinctly defined lines. It is also known in the printing industry as ‘offset’ or ‘dot gain’. It is caused by the use of laser printers, dot-matrix printers, or other types of direct-to-plate technologies. It is a serious source of aesthetic dissatisfaction, as it affects the readability of large texts, makes page edges more prominent, and affects the overall aesthetics of the document.

The purpose of lineation or set off is to increase the coverage of the most saturated colors of a printed document. The coverage of saturated colors is the ratio of ink to paper, measured as a percentage. As saturation increases, more ink is being spread over a given area, resulting in the appearance of a line. As the percentage of saturation increases, the distance between the lines and the height of the line increases.

Lineation also results from the nature of the printing process, as the use of paper with different surface textures, porosities and absorptions, can cause the laser or printing head to misread the information being printed.

The most commonly used paper type for professional printing is the glossy coated paper. This type of paper is designed to absorb the ink quickly, resulting in no lines in the final printed product. However, the use of other types of paper can result in some degree of lineation. The use of recycled papers, for example, or papers with a more absorbent surface, can cause lines to appear during printing.

Sometimes, even when the correct paper type is used, lineation can appear due to an incorrect paper configuration setting. This setting is responsible for controlling the quality of the ink coverage, and thus, the amount of lineation in the final printed product.

Are Lines Visible in the Final Print?

The answer depends on the degree of lineation present. Generally speaking, the presence of lines is more visible in photographs or images where there are areas of black. On plain text pages, the lines tend to be less visible. Lines become most visible in areas of high colour saturation. There are also certain techniques used in the printing industry, such as increasing the toner saturation or reducing the screen, that can reduce the visibility of lineation.

It is important to note that the quality of the print will also be affected by the presence of lines. The quality of a print can be measured in terms of resolution, colour accuracy, ink saturation and a range of other parameters.

In terms of resolution, a print with lineation will have a lower resolution as the lines will create a ‘stair-step’ effect when looking at the printed page magnified. The resolution of a print with lines is significantly lower than a print without lineation.

In terms of colour accuracy, a print with lines will typically have a slightly different hue in areas of high colour saturation. This is because the lines can act as a diffraction grating, separating the wavelengths of light and creating a slight colour shift. This shift can vary depending on the angle of viewing the printed page.

Finally, the presence of lines can also affect the overall printed image, as the lines can create a slightly blurred effect and reduce the overall contrast of the image. This can be particularly noticeable in photographs or when viewing the printed page at a distance.

What Causes Lines on Printed Paper?

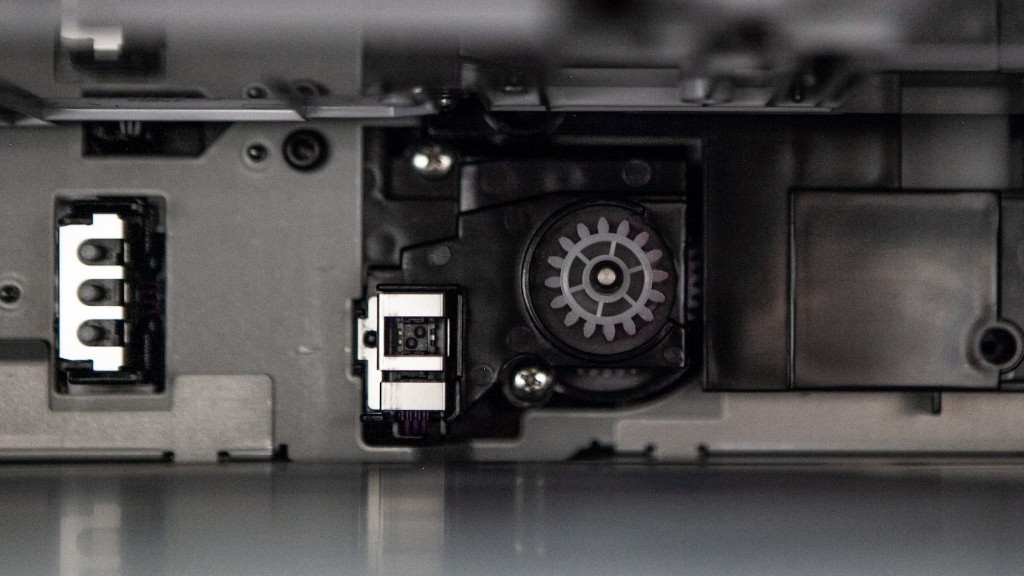

Lineation is caused by a combination of factors. As mentioned above, the type of paper used, the paper configuration setting and the degree of toner saturation all play a role in causing lines. Additionally, the printing speed, the amount of toner being applied, the type of toner used, and the condition of the toner drums can all cause lineation.

The issue can also be caused by a number of mechanical issues. Poorly calibrated printing heads, worn out toner drums, or low quality paper can all cause lines in the final product. Additionally, a dirty fuser, a bad offset blanket or a worn-out rollers on the printer can all cause lineation.

As with any printing issue, it is important to identify the root cause of the problem in order to address it properly. If the issue is caused by a mechanical problem, then it will need to be addressed on-site. If the issue is caused by other factors, such as paper type, paper configuration or toner saturation, then it may be possible to address the issue remotely through a software update.

In general, the best way to avoid lines in printed documents is to use high quality paper and ensure that the paper configuration settings are correct. Additionally, it is important to monitor the condition of the toner drums, fusers and offset blankets to ensure that they are functioning properly.

How to Fix Lines on Printed Paper

The first step to addressing lineation is to identify the root cause. If the issue is caused by a mechanical problem, such as a worn-out toner drum or a dirty fuser, then it will need to be addressed on-site. If the issue is caused by a configuration setting, such as paper type or toner saturation, then it may be possible to address the issue remotely through a software update.

Once the root cause is identified, it is then possible to address the underlying issue. If the problem is caused by a mechanical problem, then the appropriate repairs and maintenance must be carried out. If the problem is caused by an incorrect configuration setting, then it may be possible to adjust the settings to reduce the degree of lineation. Additionally, it may also be possible to reduce the printing speed or switch to a high quality paper type.

Finally, it is important to note that lineation is a common occurrence in the printing industry and many printers are designed to accommodate for it. If the lines are causing a significant problem, then it may be necessary to find a higher quality printer that is capable of achieving a higher degree of quality.

How to Prevent Lines on Printed Paper

One of the best ways to prevent lines in printed documents is to use high quality paper. Glossy coated papers are the most commonly used papers in professional printing and they are designed to absorb the ink quickly, resulting in no lines in the final printed product. Additionally, it is important to ensure that the paper configuration settings are correct in order to ensure that the printer is applying the correct amount of ink.

It is also important to use a paper thickness that is appropriate for the printer. For example, a thicker paper may be necessary when using a laser printer, whereas a thinner paper may be more suitable for an inkjet printer. Additionally, it is important to ensure that the toner drums, fusers and offset blankets are regularly checked to ensure that they are in good condition.

Additionally, it is important to be aware of the limitations of the printer. Lineation can be exacerbated if the printer is working at a higher speed than it is capable of maintaining. It is therefore important to set the printing speed to a level that the printer can handle. Additionally, it may be necessary to reduce the amount of toner being applied in order to reduce the lineation effect.

The Impact of Lines on Printed Paper

Lineation on printed paper can have a significant impact on the overall quality of the printed image. As mentioned above, the resolution of a print with lineation will typically be lower than a print without lineation. Additionally, the lines can also cause a slight colour shift, reducing the colour accuracy of the printed page. Furthermore, the lines can also create a blurred effect, reducing the overall contrast of the image.

Additionally, lineation can also affect the overall readability of the document, as the lines can make page edges more prominent. This can be particularly noticeable when viewing large texts on a printed page. Finally, the presence of lines can also affect the overall aesthetics of the document, as they can create an